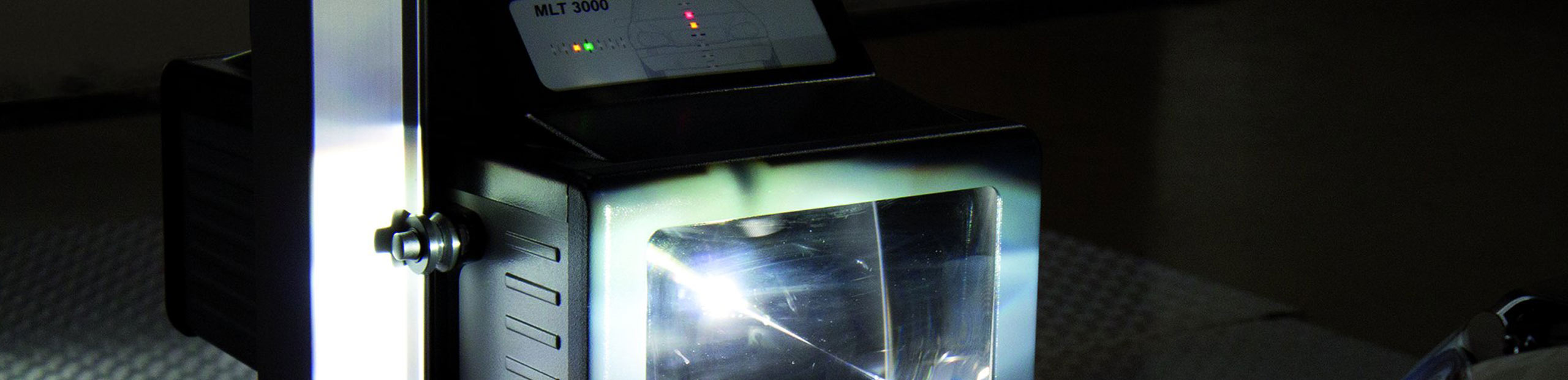

Headlight testers for trucks, buses & heavy vehicles

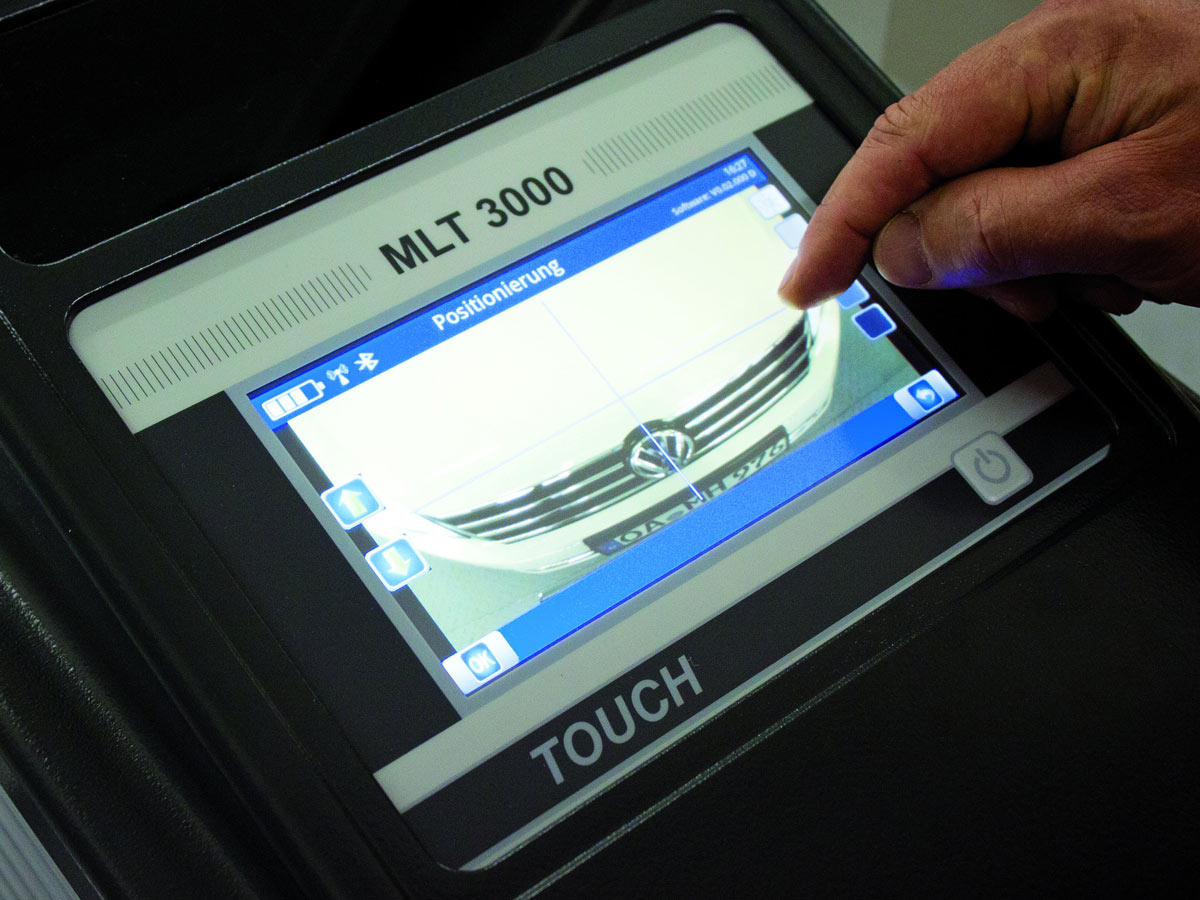

The well-organised device structure guarantees simple and intuitive use. It has a non-wearing precision guide pillar that promises a long service life, even for high-frequency use. A counterweight has been integrated into the pillar to allow the measurement housing to be lowered and raised with one hand in a smooth gliding movement, supported by a ball bearing.

The headlights are aligned via the projection screen that is visible from the side of the vehicle. Mechanical height adjustment enables the projection screen to be moved vertically in the housing. The hand wheel fitted with a scale can be used to preset the required inclination angle for the headlight.

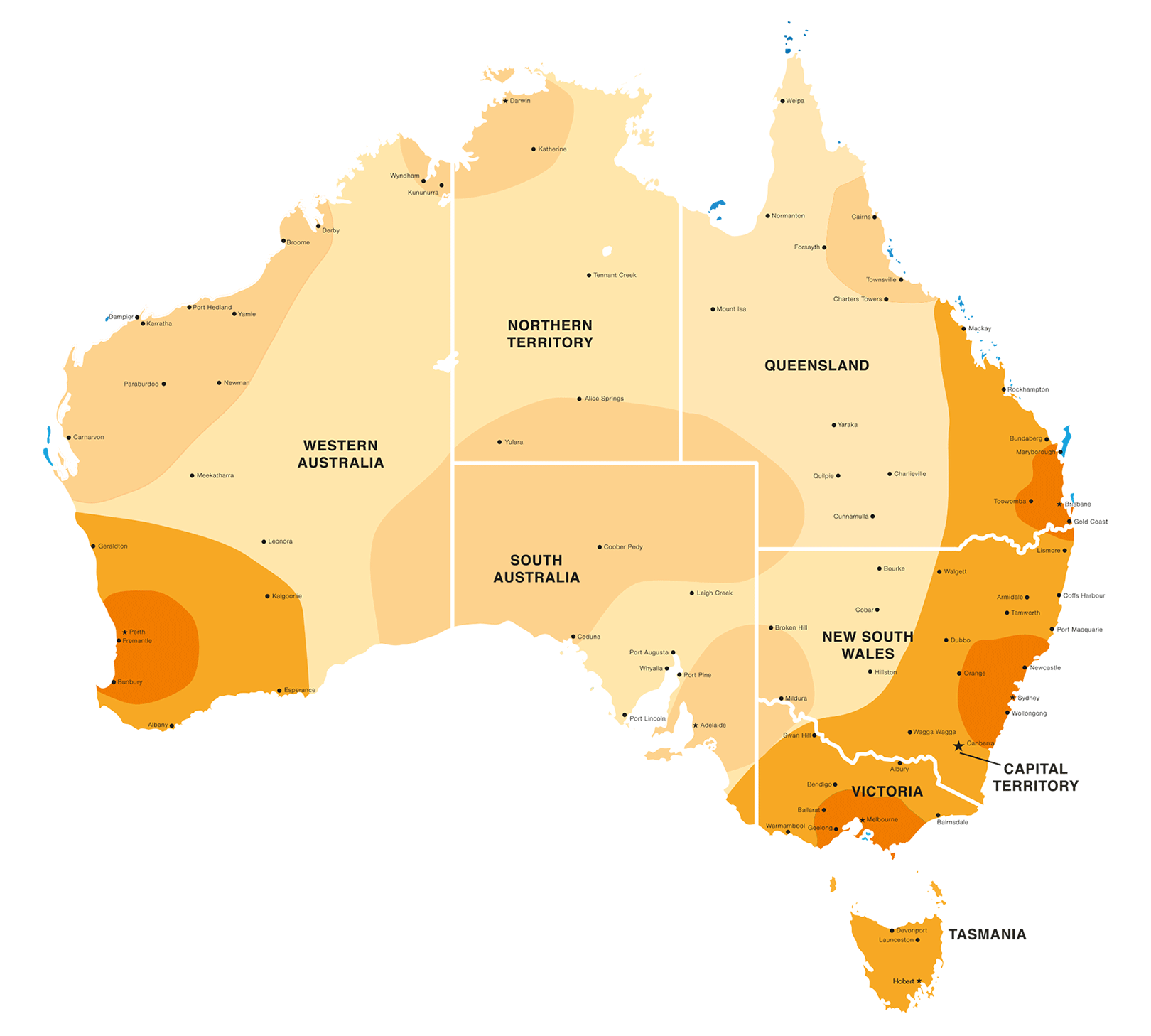

Requirements for the headlight test station

The headlight tester and test station function as a single measurement unit for identifying the cut-off line. The ‘MLT 3000’ surpasses all requirements here. Test stations need to be designed to eliminate any risk of an incorrect reading.

- The inclination* of the base surfaces for the headlight tester and for the vehicle should not exceed 1.5%.

- The difference between the inclinations of the left and right driving surface must be no greater than 0.5%. In particular, the surfaces must not slope in opposite directions.

- At all other measurement points of the driving surfaces, the unevenness* should not exceed 3 mm/m.

- The inclination of the test area corresponds to how much the test area tilts away from the horizontal base line, expressed as an angle. Unevennesses are height deviations with regard to the line of inclination, measured at various points.

MLT3000 Headlight Tester

A well-organised device structure guarantees simple and intuitive use. A counter-weight has been integrated into the pillar to allow the measurement housing to be lowered and raised with one hand in a smooth gliding movement, supported by a ball bearing. For precise alignment to the vehicle’s longitudinal axis, a laser alignment unit is available as an optional alternative to the mirror. The unit moves between the vehicle’s headlights with full directional stability thanks to individual rails, which are available in various models.