The Hartex Jacking System is fitted with swivelling axle pick up heads and come mounted into needle race equipped carriages for ease of travel along the pit opening to suit the variation on different vehicle axle centres. The pit jack carriages are designed to roll along the pit opening effortlesly.

The system has one 3kw power pack fitted under a set of stairs on one end of the pit, complete with a four station manifold, relief valve, and solenoid operated directional valves with a direct on line Motor Starter via thermal overload protection.

Hartex pit jacking system showing truck in elevated position

Hartex pit jacking system showing truck in elevated position

Newly completed RMS prefabricated workshop pit with single set of Heavy Vehicle Lifitng Jacks

Newly completed RMS prefabricated workshop pit with single set of Heavy Vehicle Lifitng Jacks

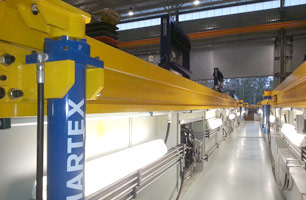

Suspended ceiling workshop pit with heavy vehicle pit jacking system installed

Suspended ceiling workshop pit with heavy vehicle pit jacking system installed

2 Sets of Hartex pit jacks shown from underneath suspended ceiling pit with pit safety cover

2 Sets of Hartex pit jacks shown from underneath suspended ceiling pit with pit safety cover

Prefabricated Drop-in Pit with Jacking System, Lighting & Ventilation & Lubrication Systems

Prefabricated Drop-in Pit with Jacking System, Lighting & Ventilation & Lubrication Systems

Our Jacking system comes with power up/down control switches to control hydraulic lifting jacks and come supplied and fitted in the pit. Lifting capacity up to 12t per pair of jacks.

A pilot operated lock valve is fitted to each lifting jack to ensure the jack stays locked in position in the event a hose bursts or a leak in the hydraulic system eventuates.